Missed Sales Opportunities: The Cost of Out-of-Stock Items

In the retail industry, out-of-stock items can significantly impact sales and customer satisfaction. Every time a customer encounters an empty shelf, it represents a missed sales opportunity. These missed opportunities not only affect immediate revenue but can also lead to long-term customer dissatisfaction and loss of loyalty. At Optimal Ascent, we understand the importance of maintaining optimal stock levels and offer expert consulting services to help businesses avoid these costly mistakes.

The Impact of Out-of-Stock Items

Out-of-stock (OOS) items are a common issue in retail, but their impact is often underestimated. Here’s why out-of-stock situations are so detrimental:

1. Loss of Immediate Sales

Direct Revenue Loss - When a product is out of stock, customers are unable to purchase it, resulting in an immediate loss of sales. This can be particularly damaging during peak shopping periods or promotions when demand is high.

Customer Dissatisfaction - Repeatedly encountering out-of-stock items can frustrate customers, leading them to shop elsewhere. This not only results in lost sales for the current visit but can also drive customers to competitors, resulting in long-term revenue loss.

2. Decreased Customer Loyalty

Brand Perception - Stockouts can negatively affect a customer’s perception of a brand. Customers expect reliability, and consistent out-of-stock situations can lead to a perception of poor management or lack of reliability.

Impact on Repeat Business - Loyal customers are the backbone of any retail business. When customers cannot find what they need, they may not return, opting instead to shop with competitors who are better at managing their inventory.

3. Opportunity Costs

Missed Upselling Opportunities - When customers encounter out-of-stock items, they miss out on potential upselling opportunities. For example, if a customer comes in to buy a specific product but ends up purchasing complementary items, a stockout means missing out on these additional sales.

Planning for Future Events - Out-of-stock situations can also hamper planning for future events. Without accurate stock data, businesses may struggle to forecast demand and plan promotions or seasonal sales effectively.

Calculating Missed Sales Opportunities

To understand the true impact of out-of-stock items, businesses need to calculate missed sales opportunities. This involves reviewing the percentage of instock items and analysing sales data. Here’s a step-by-step approach:

Step 1: Review Instock Percentage

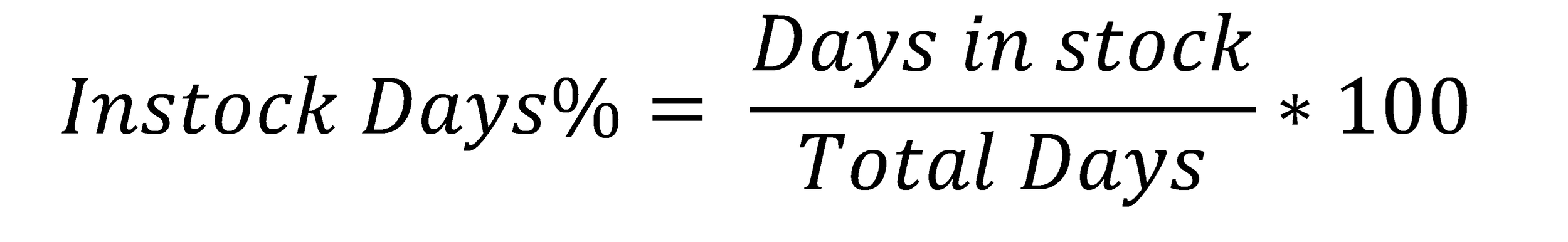

Calculate Instock Percentage - Instock percentage is the proportion of time that products are available for sale. It is calculated by dividing the number of days a product is in stock by the total number of days it should have been in stock.

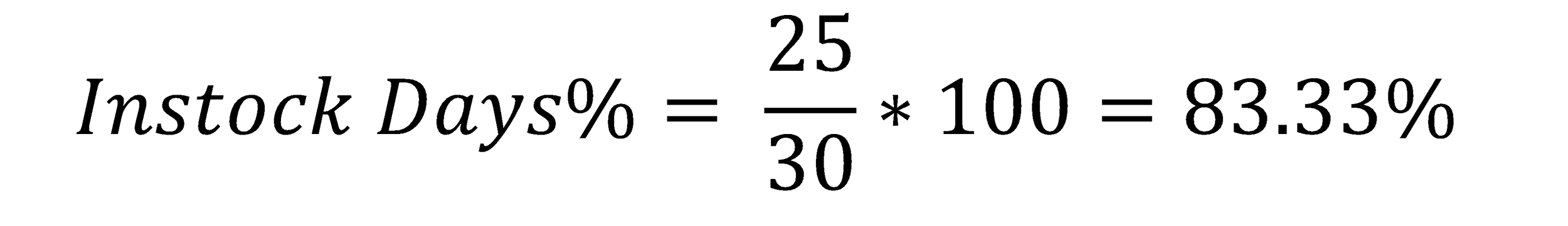

Example Calculation - If a product was supposed to be in stock for 30 days but was only available for 25 days, the instock percentage would be:

Step 2: Estimate Missed Sales

Analyse Sales Data - Review historical sales data to estimate the number of units typically sold during the period when the product was out of stock. This involves looking at sales patterns and average sales volumes.

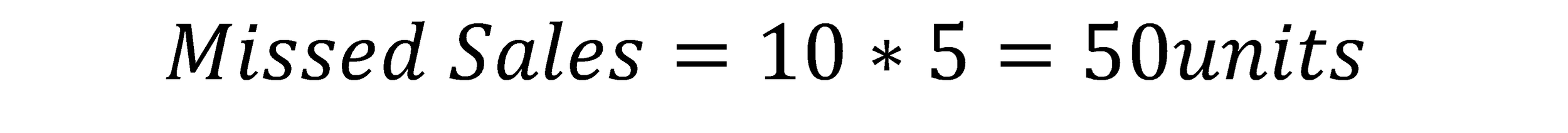

Calculate Missed Sales - Multiply the average daily sales by the number of days the product was out of stock to estimate the missed sales.

Example Calculation - If the average daily sales for a product are 10 units and it was out of stock for 5 days, the estimated missed sales would be:

Step 3: Financial Impact

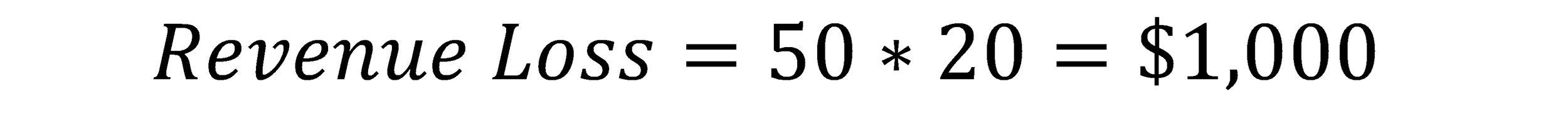

Determine Revenue Loss - To understand the financial impact, multiply the missed sales by the selling price of the product.

Example Calculation - If the selling price of the product is $20, the revenue loss would be:

This calculation provides a clear picture of the financial impact of out-of-stock situations, highlighting the importance of maintaining optimal stock levels.

How Optimal Ascent Can Help

At Optimal Ascent, we specialize in helping businesses avoid missed sales opportunities through effective inventory management and analytics. Here’s how we can support your business:

Advanced Inventory Management Systems - We implement advanced inventory management systems that provide real-time data on stock levels, helping you monitor and manage inventory more effectively.

Predictive Analytics - Our predictive analytics tools forecast demand based on historical sales data and market trends. This ensures that you have the right products in stock when customers need them, reducing the risk of stockouts.